The 8-Minute Rule for Plastic Injection Molding

Wiki Article

Things about Plastic Injection Molding

Table of ContentsEverything about Plastic Injection MoldingExamine This Report about Plastic Injection MoldingPlastic Injection Molding Fundamentals ExplainedGetting My Plastic Injection Molding To Work4 Simple Techniques For Plastic Injection Molding

After that, the mould closes and the procedure repeats. Pre-moulded or machined components can be put into the tooth cavity while the mould is open, allowing the material infused in the following cycle to create and also solidify around them. This procedure is recognized as Insert moulding as well as enables solitary components to consist of several products.

Most polymers, occasionally referred to as resins, might be utilized, including all thermoplastics, some thermosets, and some elastomers.

Offered products include alloys or blends of previously established products, so product developers can select the product with the most effective set of properties from a huge selection. Significant criteria for choice of a product are the stamina and also function needed for the last part, along with the cost, however additionally each material has various criteria for moulding that should be taken right into account.: 6 Other factors to consider when choosing an injection moulding product include flexural modulus of elasticity, or the level to which a product can be bent without damages, along with heat deflection as well as water absorption.

Unknown Facts About Plastic Injection Molding

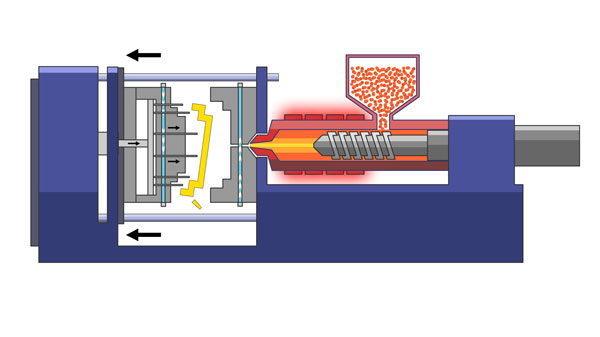

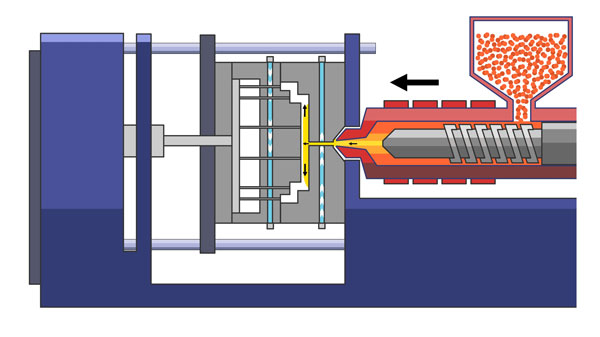

Applications consist of buckles for securing and also separating outdoor-equipment webbing. Shot moulding devices are composed of a product receptacle, a shot ram or screw-type plunger, and also a heating unit.: 240 Also known as platens, they hold the moulds in which the parts are formed. Presses are ranked by tonnage, which reveals the amount of clamping pressure that the equipment can apply (plastic injection molding).Tonnage can differ from less than 5 loads to over 9,000 loads, with the higher numbers made use of in somewhat few manufacturing procedures. The overall clamp force required is established by the predicted area of the part being molded. This forecasted location is increased by a clamp force of from 1.

As a rule of thumb, 4 or 5 tons/in2 can be utilized for many items. If the plastic material is extremely stiff, it needs more shot stress to fill up the mould, and also thus a lot more clamp tonnage to hold the mould closed.: 4344 The called for force can additionally be figured out by the material utilized and also the size of the component.

Mould or die are the usual terms made use of to describe the tool utilized to create plastic components in moulding. Since moulds have been expensive to produce, they were normally just made use of in mass production where thousands of parts were being produced.

9 Easy Facts About Plastic Injection Molding Explained

Injection moulding die with side draws "A" side of die for 25% glass-filled acetal with 2 side pulls. "B" side of die with side pull actuators. Basic two plates tooling core and also tooth cavity are inserts in a mould base "household mould" of five various parts The mould consists of two navigate to this website key elements, the injection mould (A plate) and also the ejector mould (B plate).Plastic material enters the mould via a or entrance in the injection mould; the sprue bushing is to secure firmly against the nozzle of the shot barrel of the moulding device and also to enable molten plastic to move from the barrel into the mould, additionally understood as the cavity.: 141 The review sprue bushing directs the liquified plastic to the tooth cavity photos with channels that are machined right into the faces of the An and B plates - plastic injection molding.

(A) Sprue, (B)&(C)runner as well as (D)gates in real injection moulding item for toys The amount of material required to fill up the sprue, jogger and dental caries of a mould comprises a "shot". Entraped air in the mould can escape with air vents that are ground right into the parting line of the mould, or around ejector pins and slides that are somewhat smaller sized than the holes keeping them.

The air can also become so compressed that it sparks and also burns the surrounding plastic material.: 147 To permit elimination of the moulded part from the mould, the mould functions need to not overhang one an additional in the direction that the mould opens, unless parts of the mould are created to relocate from between such overhangs when the mould opens up making use of components called Lifters.

Plastic Injection Molding for Beginners

The coolant soaks up warmth from the mould (which has actually soaked up warmth from the warm plastic) and also keeps the mould at an appropriate temperature level to strengthen the plastic at one of the most efficient rate.: 86 To relieve maintenance and venting, cavities and also cores are separated right into pieces, called inserts, as well as sub-assemblies, also called inserts, blocks, or chase blocks.Extra intricate components are developed using more intricate moulds. These might have sections called slides, that move right into a tooth cavity perpendicular to the draw direction, to create overhanging part attributes. When the mould is opened up, the slides are pulled away from the plastic part by making use of fixed "angle pins" on the stationary mould fifty percent.

The component is then expelled as well as the mould closes. The closing activity of the mould triggers the slides to move onward along the angle pins.: 268 A mould can create numerous copies of the very same parts in a single "shot". The variety of "impressions" in the mould of that component is usually improperly referred to as cavitation.

The 6-Minute Rule for Plastic Injection Molding

This system can permit production of one-piece tires and also wheels. Two-shot or multi-shot moulds are developed to "overmould" within a solitary moulding cycle and should be refined on specialised injection moulding makers with two or more shot devices. This procedure is really a shot moulding process carried out two times and therefore has a much smaller margin of mistake.

Report this wiki page